In the world of manufacturing, efficiency and productivity are key factors that can significantly impact a company’s success. As CNC (Computer Numerical Control) machines play a pivotal role in modern production processes, finding ways to optimize their operation becomes crucial. Modo Eight, a leader in robotics and automation, presents two innovative solutions, the Modo-Tend U and Modo-Tend F, designed to revolutionize CNC machine tending and take productivity to new heights.

Introducing Modo-Tend U and Modo-Tend F:

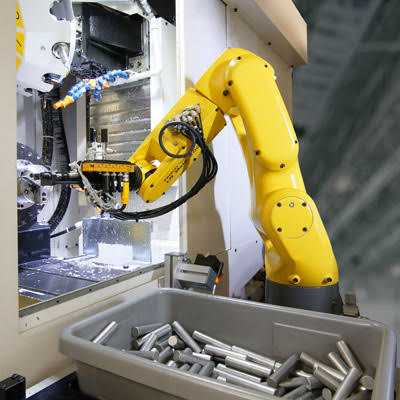

Modo 8’s robotic machine tending stations, the Modo-Tend U and Modo-Tend F, offer cutting-edge automation for CNC operations. These modular and cost-effective solutions are meticulously designed to cater to various production environments and streamline the manufacturing process.

- Versatility and Compatibility: The Modo-Tend U and Modo-Tend F are available in drawer or tray configurations, allowing seamless integration with diverse CNC machines. Furthermore, these tending cells are compatible with a wide range of accessories, making them adaptable to the unique requirements of different production setups.

- Enhanced Autonomy: One of the standout features of Modo 8’s machine tending solutions is their ability to provide up to a full day of machine autonomy. By automating the loading and unloading of workpieces, these stations enable continuous production without the need for constant human intervention.

- Collaborative Robot Capability: Modo 8 offers the flexibility of using collaborative robots, such as Ur or Fanuc robots, for machine tending operations. These robots work safely alongside human operators, creating a harmonious and efficient production environment.

- Handling High Volume and High Mix Production: The tending cells are engineered to handle high volume production requirements, ensuring rapid and consistent processing of a large number of workpieces. Additionally, Modo 8’s solutions excel in high mix production environments, effortlessly adapting to varying product types and specifications.

- Customization and Mobility: Modo 8’s commitment to meeting unique customer needs is evident in its approach to customization. The machine tending stations can be tailored to specific requirements and preferences, whether that involves fixed installations or mobility for greater flexibility on the production floor.

Beyond Standard Products:

While the Modo-Tend U and Modo-Tend F offer comprehensive solutions for CNC machine tending, Modo 8’s capabilities extend far beyond standard products. With a team of experienced engineers at the helm, the company is well-equipped to address specific challenges and develop tailored solutions for diverse applications.

Conclusion:

Modo Eight’s robotic machine tending solutions, the Modo-Tend U and Modo-Tend F, embody the future of CNC automation. By optimizing productivity, reducing manual intervention, and providing unmatched adaptability, these tending cells empower manufacturers to enhance their overall production efficiency. Whether you operate in a high volume or high mix production environment, Modo 8’s solutions are designed to elevate your CNC operations to new heights. Reach out to Modo 8 today and unlock the potential of automation for your manufacturing processes.